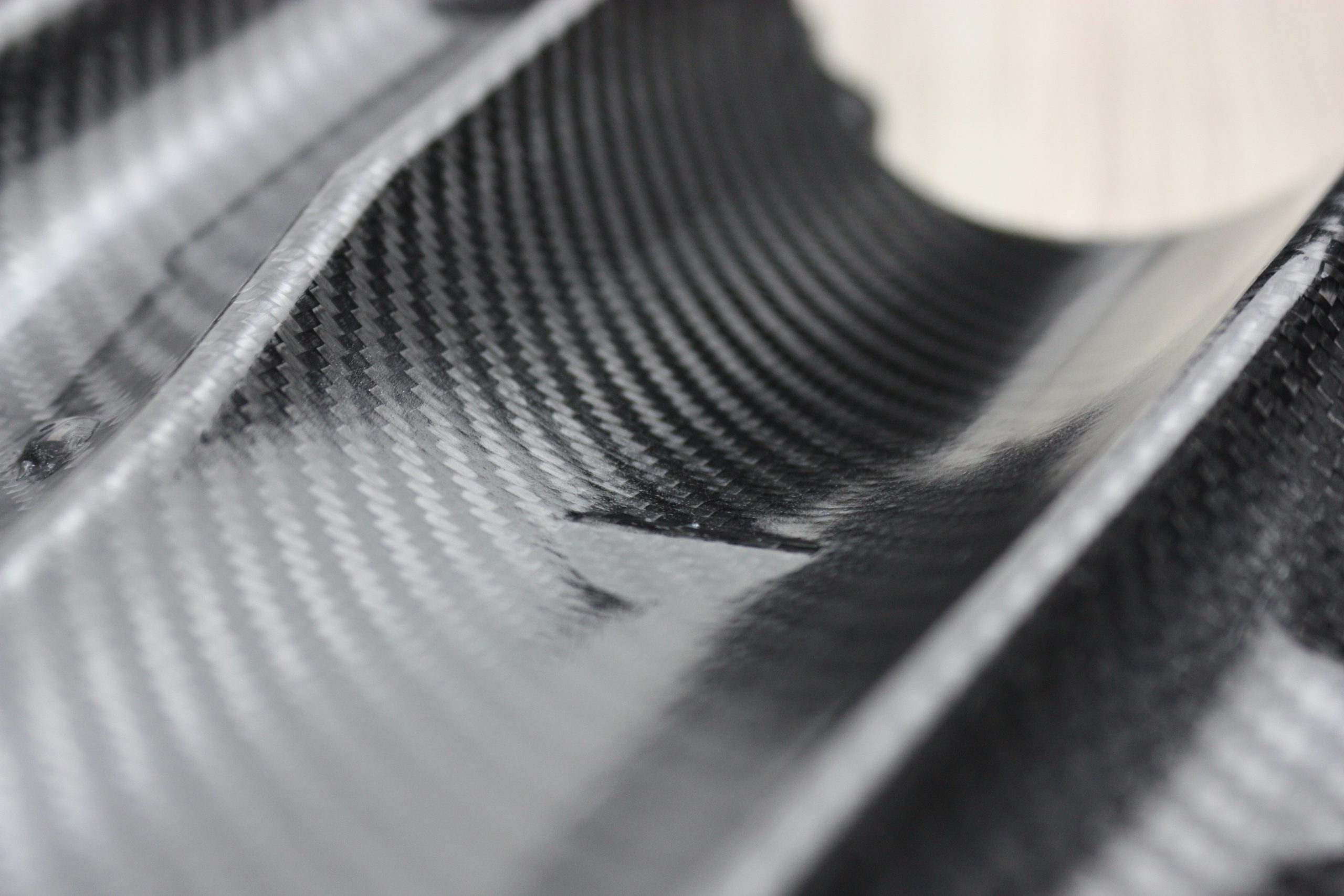

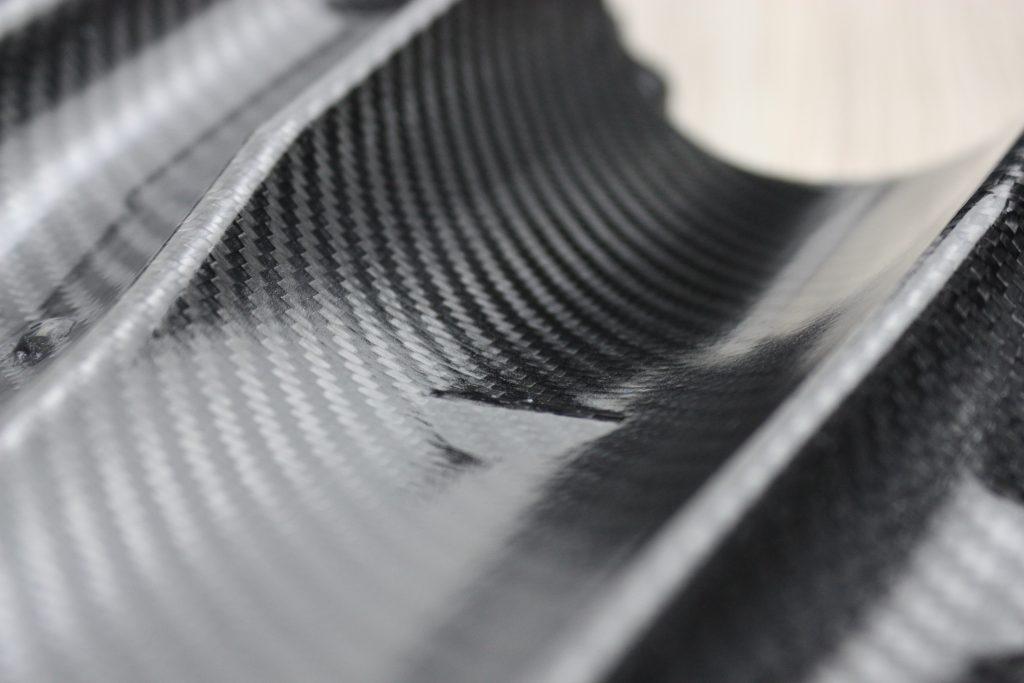

In a bid to champion eco-friendly manufacturing, GTR is trialling the latest offering from SHD – LTB300. GTR, already an advocate for sustainable practices, has been utilizing SHD’s existing bio-derived tooling system LTB310 for nearly a year with excellent results.

GTR’s proactive approach is rooted in a relentless pursuit of improved systems, not only to benefit their operations and clients but also to minimize their environmental impact. This year has seen GTR consume record amounts of tooling materials of various types.

Their commitment to reducing the environmental footprint while maintaining superior quality standards is evident in their shift towards bio-derived resin types, precisely applied where appropriate. This strategic move aligns with their dedication to responsible manufacturing.

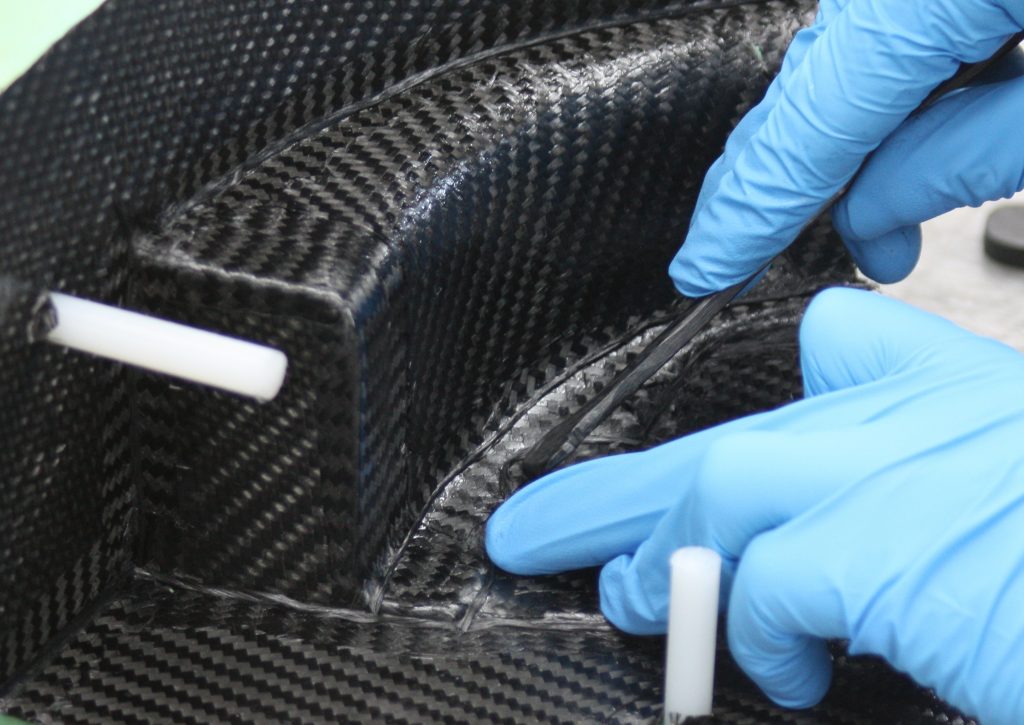

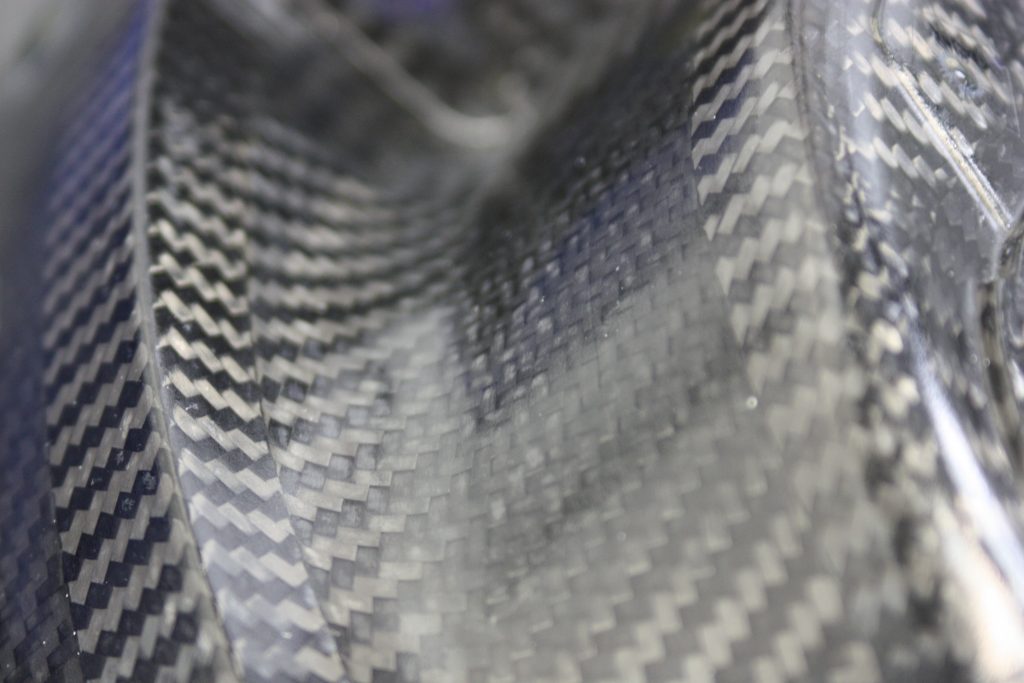

Notably, all carbon fibre tools at GTR are meticulously handmade, reflecting the dedication and craftsmanship invested in their production. As GTR strides forward in its eco-friendly initiatives, their endeavours in sustainable tooling systems signal a promising future where innovation and environmental consciousness go hand in hand.

Furthermore, GTR’s success in consistently sourcing the best materials can be attributed to their robust supplier partnerships. The diversity of GTR’s projects, ranging from automotive (including F1), marine, to aerospace industries, underscores their expertise and adaptability. The tools crafted by GTR this year span a wide size spectrum, from as small as the palm of a hand to as large as a family car, showcasing their versatility and proficiency.

Their studies also extend to other materials impregnated with bio-derived products such as MTB350 and GTR will continue to test and experiment with such products so they can offer these to customers with an excellent understanding of how these products handle and perform.