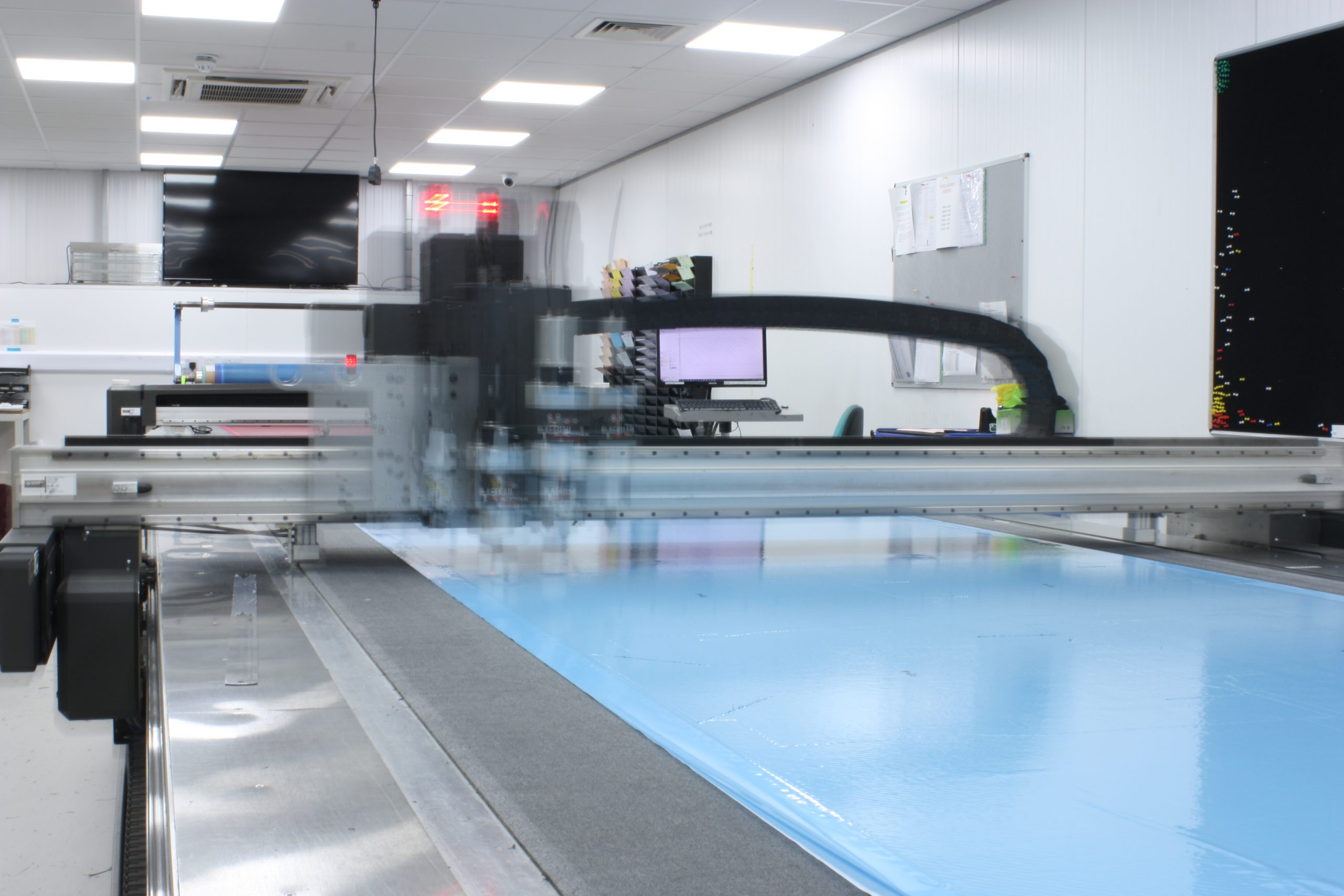

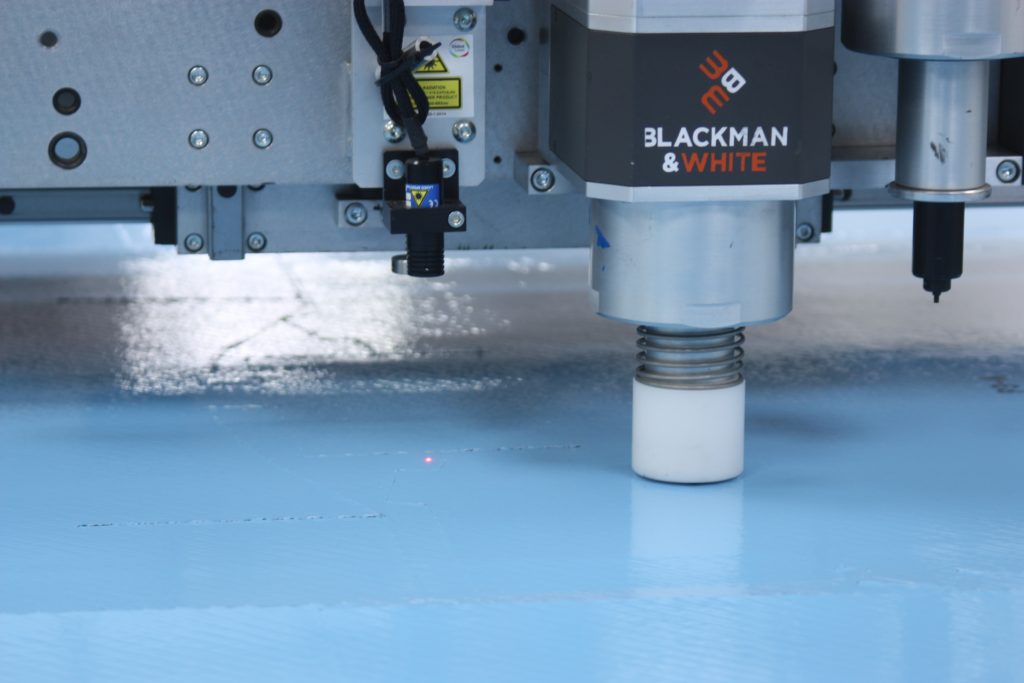

As a leader in the composite manufacturing industry, GTR constantly strives to refine their processes and increase efficiencies during production. One example of this is demonstrated by GTR now running a pair of Blackman & White Genesis CNC cutting machines. The machines can be operational for as many hours of the day and/or night, as required.

GTR’s dedication to staying at the forefront of composites manufacturing is exemplified by the integration of these machines into the production process. Blackman and White are recognised as industry leaders in their field and provide unrivalled precision and efficiency in cutting raw composite material. The machines offer a level of speed, accuracy and usable interfaces that set new industry standards. Capable of handling challenging materials like kevlars, aramids, and flame-retardant foams, these machines elevate GTR’s capabilities beyond the more traditional methods previously employed.

GTR has demonstrated that the machines play a pivotal role in achieving optimum efficiencies, especially during extended production runs where minor gains translate into significant financial and operational advantages. The integrated software not only optimises material usage but also streamlines cutting paths, saving valuable time. The machines contribute to traceability by individually bagging each kit with its paperwork and barcode, assigning unique freezer locations recorded on the MRP system.

Rooted in motorsport, GTR’s innovative approach has facilitated expansion into diverse sectors. The ability to translate 3D CAD models into labelled kits, complemented by lay-up manuals, ensures a user-friendly experience in the clean room. This not only enhances operational efficiency but also acts as a quality control safety net, preventing the use of incorrect materials in components.

Beyond traditional applications, GTR’s CNC machines offer versatility by converting paper templates to CAD files. This flexibility is invaluable in instances where appropriate files are unavailable, such as in prototype or research and development projects.

We’d be delighted to hear from any business seeking the ultimate in composite kit cutting with a focus on time and material savings – please do get in touch with our team here at GTR. Working together, we can help to elevate your manufacturing processes, ensuring efficiency, accuracy, and unparalleled quality in every component produced.